Typically applied for abrasive blasting, pressure washing and inspection of hydropower station penstocks and other pipes interior.

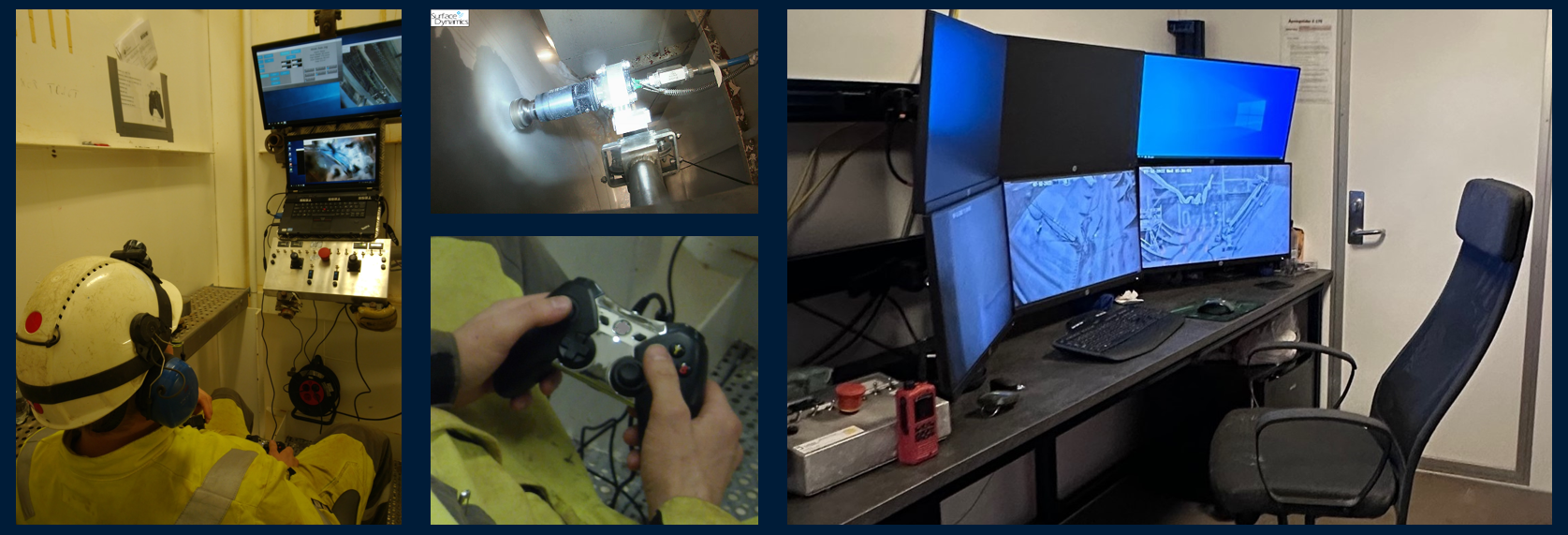

Simple and robust 3-axis robot system developed by Surface Dynamics. Using steel rope winch for pipe inline propulsion. Remote and semi-auto controlled, operated using real-time video to operator monitor.

Fits pipe dimensions from Ø400mm up to Ø5000mm and capable of lengths more than 1000 meters.

Track record of more than 3500 hours and 30.000 sqm area of abrasive blasting penstocks interior. Peak performance 250sqm of abrasive blasting pr 24h shift.

Robot Control and Operator Station

Remote jog or programmed motion, supported by real-time video streaming to operator monitor.

RobotOS and Simulator

- For Work Planning, Documentation, Robot Control and education.

- Asset specific 3D background import for realistic training, work planning and pre-programming.

- Real time video of tool process presented to operator screen, backed by simulator view.

- Kinematic tool control.

References System P

| 2023 | Solidenergy AS | Aurland Hydropower Station 2023, owned by Hafslund Eco and Statkraft, penstock abrasive blasting, 12 500kvm |

| 2021 | Solidenergy AS | Rana Hydropower Station 2021, owned by Statkraft, a robot rental service for abrasive blasting of penstock interior. |

| 2021 | Solidenergy AS | Letten Hydropower Station 2021, Sweden, owned by Fortum, a robot rental service for abrasive blasting of penstock interior. |

| 2021 | Solidenergy AS | Matre Hydropower Station 2021, owned by BKK, a robot rental service for abrasive blasting of penstock interior. |

| 2021 | Solidenergy AS | Holsbru Hydropower Station 2021, owned by Hydro, a robot rental service for abrasive blasting of penstock interior. |

| 2017 | Solid Vedlikehold AS | Frøland Hydropower Station 2017, owned by BKK, a robot rental service for abrasive blasting of penstock interior. |

| 2017 | Solid Vedlikehold AS | Tunnsjødal Hydropower Station 2017, owned by NTE, a robot rental service for abrasive blasting of penstock II interior. |

| 2017 | Solid Vedlikehold AS | Tafjord Hydropower Station 2017, owned by Tafjord Kraft, a robot rental service abrasive blasting of of penstock internior. |

| 2017 | Solid Vedlikehold AS | Lio Hydropower Station 2017, owned by Statkraft, a robot rental service for abrasive blasting of penstock interior. |

| 2016 | Solid Vedlikehold AS | Tunnsjødal Hydropower Station 2016, owned by NTE, a robot rental service for abrasive blasting of penstock I interior. |

| 2016 | Statkraft | Jostedal Hydropower Station 2016, Sogn og Fjordane, owned by Statkraft – inspection and video documentation of all welded seems in the 700 meters long penstock of diameter Ø2600 mm. |

| 2015 | Solid Vedlikehold AS | Myruverket Hydropower Station 2015, Faroe Islands, owned by SEV – a robot rental service for abrasive blasting of penstock interior. |

Contacts