Our products

The steps of robotic execution

(Robotic surface treatment generally follows the same processes and standards as with conventional, manual execution)

1. Fresh water cleaning if required

Standard pressure washing nozzle integrated on the robot.

2. Pre inspection and documentation

Video documentation of surface and specific findings. Dry film thickness for reference before abrasive blasting.

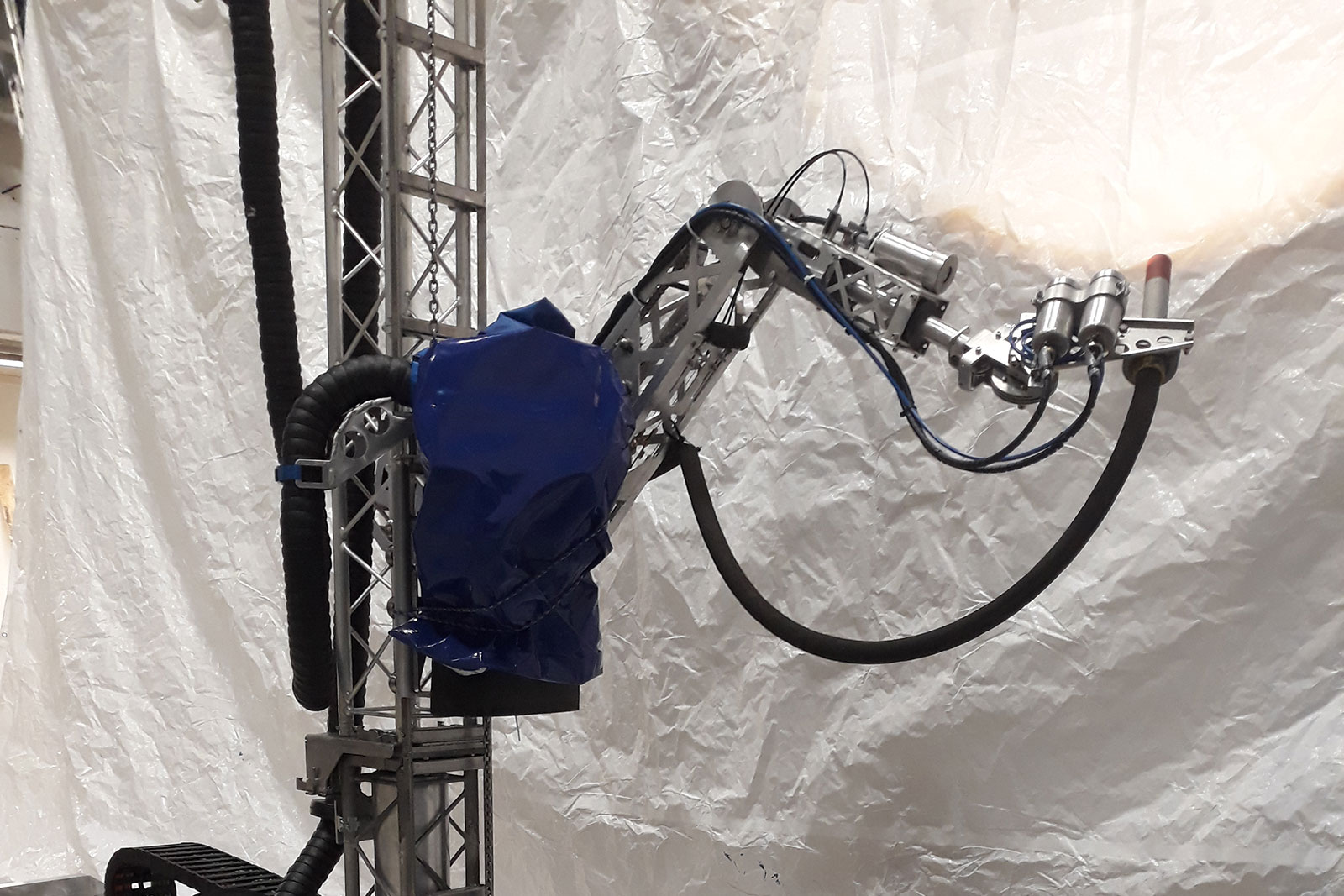

3. Surface cleaning (abrasive blasting or water jetting).

Selected nozzles attached. Working pressure at nozzle end verified. Abrasives chosen according to paint specification. Climate conditions continuously monitored and documented, with alarm level signaling to robot operator control panel. Shortly after abrasive blasting startup, the surface cleanliness, surface profile as well as test on salt contamination is verified. After finished abrasive blasting, the robot is applied in dust cleaning by air-only blasting of surface and then finally vacuuming before dust cleanliness is verified and documented by testing.

4. Inspection and documentation of clean surface before painting

Clean surface inspection and documentation. Surface profile, cleanliness, salt contamination test and climate conditions documented.

5. Stripe coating

Stripe coating executed by the robot, on welds and edges according to standards and coating system data sheet and application notes. Remote/jogging control of robot while stripe coating. The same procedure is applied in cases of surface repair or smaller spot repair maintenance. Robotic stripe coating is performed either by brush or airless spray. Correct coating thickness verified by robot executed DFT.

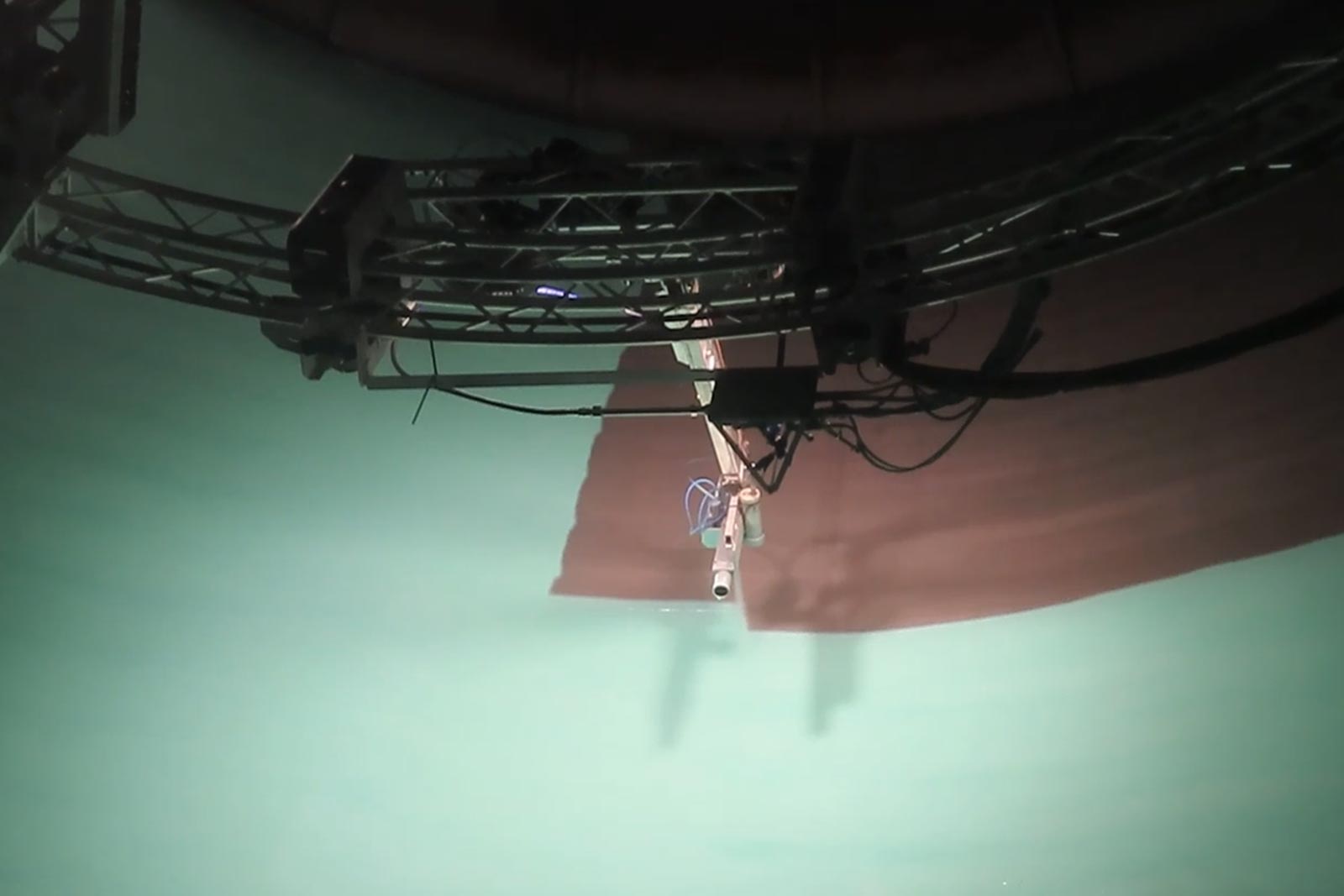

6. Painting

Correct nozzle size and spread selected. The robot’s applied nozzle speed and spray image overlap selected from conversion tables to secure correct nominal coating thickness. Robot motion programs uploaded and prepared for start-up. Robot operator and paint handling personnel team briefing and preparation. Quick spray paint wet film thickness verification test run on test panel right before start. Spray painting then executed and completed. In case of any spray paint image irregularities during operation, the auto-clean sequences is performed after stopping the robot, with automatic flipping of nozzle 180 deg, a second of paint spit into the onboard waste box, flipping the nozzle back again, reversing the robot motion past the stop point and then continouing spray painting operation.

7. Inspection of surface after painting

Robot operator monitors the paint work in progress through real time video. Critical points such as weld seams and edges are exercised while equipment is still active. Inspection at this point is of non-contact to surface.

8. Data collection (coating thickness, wall thickness, etc)

After curing of coating the data collection starts with dry film thickness measurements. Data is presented in tables and graphics.