Typically applied for cleaning, painting, inspection and data collection of tanks and voids.

Articulated rail robot developed by Surface Dynamics. NORSOK Z-015 and ATEX Zone 2 conformity. Remote- and auto controlled, utilizing real time video to operator monitor.

The system is entered into workspace in modules, with capability of passing personnel openings of diameter Ø500mm, and being assembled inside the work area in 30 minutes.

Standard vertical range 7 meters, horizontal range 6 meters in each direction. Can be reconfigured for extended range. Total weight of standard edition is 230kg.

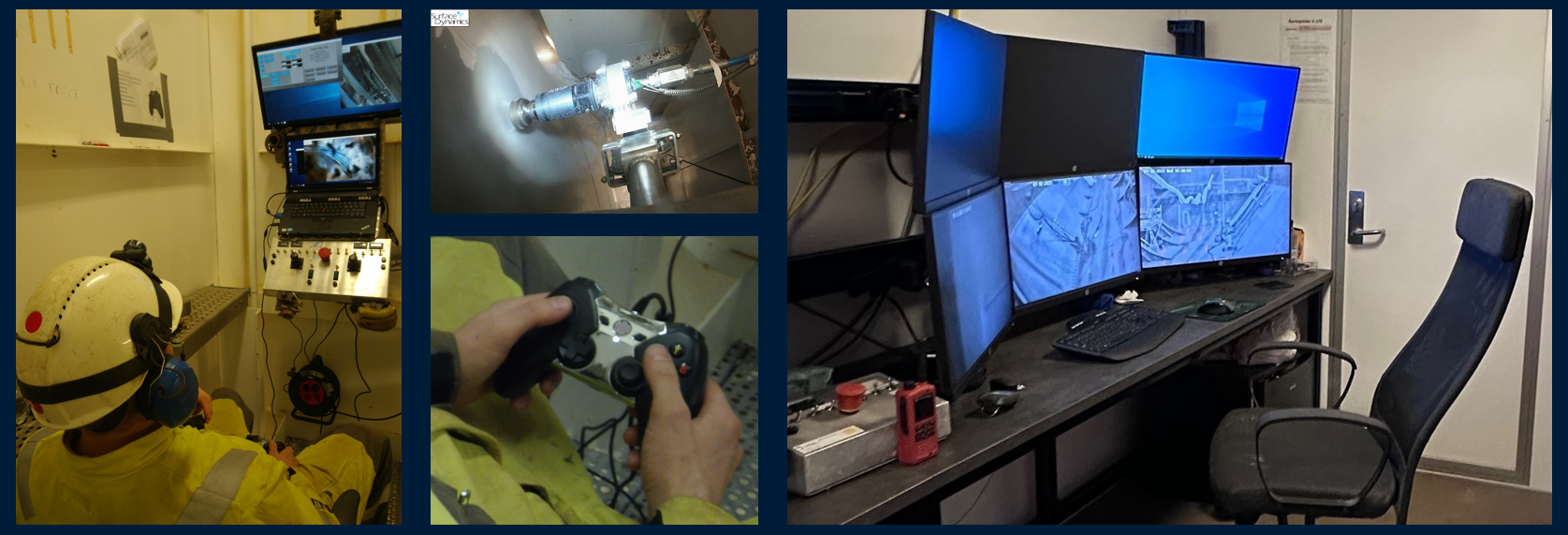

Robot Control and Operator Station

Remote jog or programmed motion, supported by real-time video streaming to operator monitor.

RobotOS and Simulator

- For Work Planning, Documentation, Robot Control and education.

- Asset specific 3D background import for realistic training, work planning and pre-programming.

- Real time video of tool process presented to operator screen, backed by simulator view.

- Kinematic tool control.

References System T

| 2023 | Equinor | H2S Scavenger Drain Tank abrasive blasting, 2 tanks at production platform in the North Sea |

| 2022 | Equinor | Mud tanks abrasive blasting and robotic abrasives vacuuming, 6 tanks at production platform in the North Sea. |

| 2022 | Equinor | Potable water tanks abrasive blasting and robotic abrasives vacuuming at FPSO in the Norwegian Sea. |

| 2021 | Shell Int Exploration & Production, Houston | Offshore robotic demo of abrasive blasting on deck surface, at production platform GoM, USA |

| 2021 | Equinor | Rundown tanks interior surface preparation at production platform in the North Sea 2021 |

| 2021 | Equinor | Pig launcher interior surface preparation and spray paint pilot on platform in the North Sea |

| 2019 | Equinor | Water ballast tank exterior surface preparation on production platform in the North Sea 2019 – UHP, 11m height |

| 2019 | Equinor | Drilling water tank (conversion) surface preparation on platform in the North Sea 2019 – abrasive blasting of, 1700sqm. |

| 2019 | Equinor | Ballast tank final section surface preparation at FPSO in the Norwegian Sea 2019 – spot abrasive blasting of, 10 compartments 1100sqm. |

| 2019 | Equinor | Pressure vessel interior surface preparation on platform and turnaround in the North Sea 2019 – abrasive blasting of, size Ø5m x 14m. |

| 2019 | Shell Int Exploration & Production, Houston | Onshore robotic demo of surface cleaning using various cleaning tools on a ballast tank structure, Houston, Texas, USA 2019 |

| 2019 | Equinor | Potable water tank interior surface preparation on production platform in the North Sea 2019 – abrasive blasting of, 120sqm. |

| 2018 | Equinor | Water ballast tank on a fixed leg platform in the North Sea 2018 – robot rental service for UHP water jetting of tank exterior, 10 meters height. |

| 2018 | Equinor | Potable tank interior on platform in the North Sea 2018 – robot rental for abrasive blasting of, 2 tanks 150sqm each. |

| 2018–2019 | Equinor | Pilot project of robotic surface treatment and coating of petroleum storage tanks in Norway 2018 – 2019. |

Contacts